Fully Automated Glass Edging and Polishing Equipment Solutions

Main Techincal Parameter

|

MODEL No. |

ZXX-C2010 |

ZXX-C2515 |

ZXX-C3015 |

ZXX-C4020 |

|

Machine Bed |

Heavy heat treatment bed |

|||

|

Internal of machine structure |

Half Cover/Waterproof design, 304 stainless steel outer cover and inner cover |

|||

|

Control System |

QIXIN SYSTEM (ZNXU Special designed) |

|||

|

Main Spindle |

DIAM θ150 / θ100 |

|||

|

Machine Size |

3600*2150*2300MM |

4100*2650*2300MM |

4600*3150*2300MM |

5600*3650*2300MM |

|

PKG. SIZE |

3700*2200*2200MM |

4100*2250*2200MM |

4600*2250*2200MM |

5600*2600*2200MM |

|

N.W(kg) |

2500KG |

2750KG |

3450KG |

4000KG |

|

Table Size |

2000*1000MM |

2500*1500MM |

3000*1500MM |

4000*2000MM |

|

Work Travel |

2000*1000*380MM |

2500*1500*380MM |

3000*1500*380MM |

4000*2000*380MM |

|

Mini grinding size |

100*100mm ( FOR SMALLER SIZE CAN ALSO BE DONE BY CUSTOMIZED SUCKER) |

|||

|

Max grinding size ( wheel φ100) |

1900*900MM |

2400*1400MM |

2900*1400MM |

3900*1900MM |

|

Max cutting size |

2000*1000MM |

2500*1500MM |

3000*1500MM |

4000*2000MM |

|

Speed |

Grinder <15M/MIN, Polish <6M/MIN |

|||

|

MaxMilling Speed |

600mm/min |

|||

|

Table Material |

Aluminium Plate AFTER CNC MILLING |

|||

|

Position Accuracy |

0.02mm |

|||

|

Repeated position accuracy |

0.1mm |

|||

|

SERVO DRIVE |

DELT |

|||

|

ELECTRIC |

SIEMENS |

|||

|

LIMIT SWITCH |

OMRON |

|||

|

VFD |

SINEE |

|||

|

POWER REQUEST |

AC/380V/50HZ/24KW, 3Phase |

|||

Product introduction

The PC based numerical control work center is dedicated to the glass processing. Cutter heads can be moved left and right,up and down through the three-axis linkage structure controlled.

The base, the columns & beams are made of Heavy iron to ensure the stability of the machine for long-term operation.

The drive adopts servo motor, and the sliding adopts imported high-precision linear guide rail to ensure running, slider and ball screw, which ensures the accuracy requirement during operation.

The design concept of this machine is to provide cost-effective equipment for glass deep processing enterprises, the structure is as simple as possible, more functions are combined as much as possible, and the operation is as simple as possib

Product advantages

DOUBLE STATION PROCESSING:Two glass can be loaded at the same time. By this feature after the first glass processing the machine automatically reposition itself for second glass. Thanks to this feature time losses caused by glass loading is prevented and serial glass processing increased in production.

MULTIFUNCTION PROCESSING: With its multifunction glass processing feature our machine can do glass edging, milling, drilling and polishing automatically in one cycle for flat and shaped glasses. This feature is very useful for manufacturing of glass doors, furniture glasses, shower glass doors etc.

PROPORTIONAL HANDWHEEL: With its hand held unit that we have developed for our glass processing center the operator is able to use the machine through hand held unit easily with maximum comfort. Proportional and ergonomically designed handwheel is used for precise, fast reset and setup purposes.

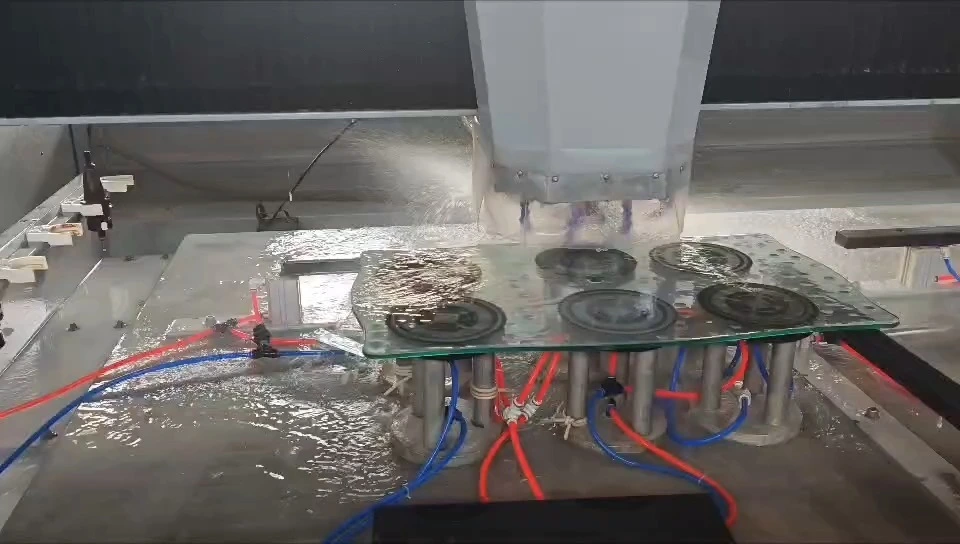

SUCTION CUPS SUPPORT SYSTEM: Holding the glass in glass processing is one of the important case and by knowing that very well we have designed strong suctions cups which has long life usage. With our strong suction cups technology we offer you maximum safety and the easiest way of glass processing with our glass processing center.

REMOTE ACCESS SYSTEM: Remote technical assistance system based on a set of software tools that allows authorized staff of our after sales services to manage maintenance or assistance tasks anywhere in the world quickly and efficiently. Access via the Internet is always done with theprior consent of the customer.

Name: suyala

📞 Get in Touch:

WhatsApp/WeChat: +86 15588110989

Email: suyala@znxuglassmachine.com

- +86 15969955501

- +86 15588110989

121 Yanan Road, Economic Development Zone, Linyi City, Shandong Province, China